SUSTAINABILITY

WHY LEATHER?

First circular economy of humanity

Leather is a waste from other industries. The material is dignified and ennobled. The leather industry is recycling a waste.

|

|

Did you know that if it is not used, it has to be burned, thus causing more pollution? |

|

|

The animal is raised for its skin? False |

FULL ANIMAL, NATURE AND HUMAN SYNERGY

The synergy and collaboration of all parties is essential. Humans have the responsibility to take care of the environment. In order to be able to cultivate and feed, it is essential to collaborate with the animal. By taking proper care of the animal, nature is maintained and the life cycle of all species and plants continues.

|

|

Did you know that the best fertilizer that crops can have comes from livestock? |

|

|

From a residue, the synergy livestock/farming reduces the dependence on synthetic fertilizers. |

SUSTAINABILITY AND DEVELOPMENT

Doing the above correctly allows a sustainable growth of the ecosystem and an appropriate development of the agricultural areas dedicated to it.

This helps to maintain the forests and avoid fires, among other problems.

Intrinsically it helps the development of villages and rural areas.

|

|

Did you know that the herds, by feeding themselves, clean the forest and regenerate it, thus helping to keep it from dying and preventing fires? |

|

|

Do you like to go to a village and see that there is live in it? Without agriculture and livestock this would not be possible. |

DURABILITY AND ECOLOGY

Taking into account the durability of the product, it is a material with a very low carbon footprint. Currently tanneries are already working so that the impact is zero.

A well-treated leather product is able to pass from generation to generation.

In manufacturing, the waste water used is properly treated in purification plants for subsequent reuse.

All leather manufacturing processes are optimized for the use of its residues.

Did you know that after the tanning process the water passes through a purification system to be reused?

|

|

Did you know that the rests of the raw material process are reused? An article is made for stuffing or support for bags, belts, bookbinding... |

|

|

Did you know that the remains of tanning are used to manufacture adhesives, cosmetics, gelatine, absorbent products and fertilizers, among others? |

|

|

Did you know that leather, being rich in carbon, nitrogen and oxygen, degrades and decomposes much faster than synthetic materials? |

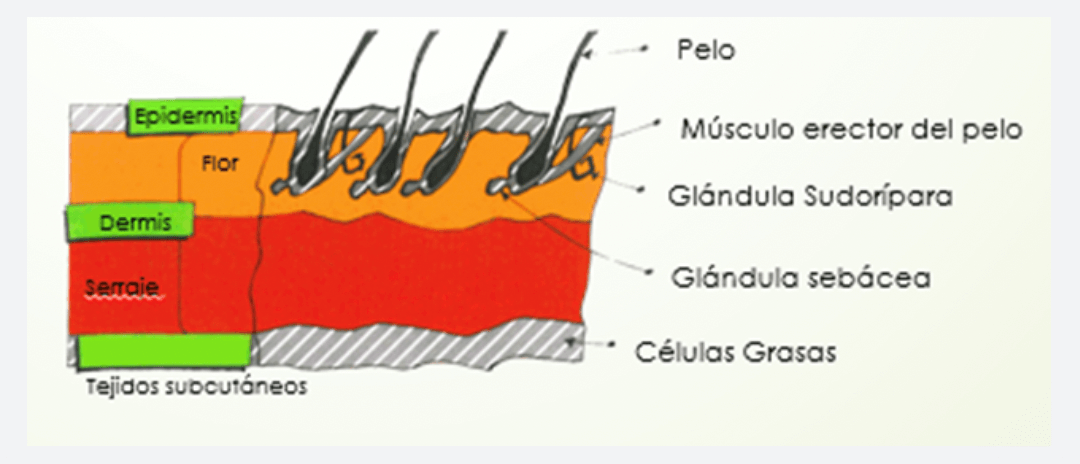

WHAT IS LEATHER?

The leather is the covering of the animal, the epidermal structure of the animal. The international definition does not allow disintegrated or reformed articles to be referred to as such.

|

|

Did you know that it is not possible to talk about synthetic fur? If it is done, it is to confuse the consumer and because at a marketing level they consider that talking about the term fur positions them as a high quality article. |

WHAT TYPE OF LEATHER CAN I MAINLY FIND?

-

Bovine: Scientific name Bos Taurus, they are bull, ox, steer, cow, calf, skin of great surface, quality, thickness and resistance suitable for all kinds of products of different sectors.

-

Sheep: It is a small skin, they are sheep and lambs, lighter and softer than bovine, it is more elastic and comfortable to manufacture garments.

-

Caprine: It's a small skin, more resistant than sheepskin, with a larger pore and a firmer and more compact fiber, making it less elastic than sheepskin.

WHAT PARTS OF THE SKIN ARE USED?

-

Nubuck: Upper grain, supperficially polished to achieve a velvety touch.

-

Suede: Instead of working the upper part (grain), the part attached to the meat is worked.

-

Split leather: Obtained by dividing the leather in two. The lower part has no grain, it is only fiber. If not worked, it has a velvety effect.

WHY DOES LEATHER HAVE DEFECTS

It is precisely the naturalness of the material that will always have defects and irregularities. Precisely because it is a natural product, its characteristics may be different. The marks, grains... are due to the type of life of the animal ant the geography where it has lived. One skin will never be regular and equal to another, certain areas of the skin will be more sagging and with more wrinkles.

|

|

Did you know that the most valued in the leather expert is its irregularity and its aging over time? |

HOW IS THE LEATHER MANUFACTURING PROCESS?

-

Salting of the skin (to avoid putrefaction)

-

Ribbing process (process of elimination of the hair):

-

Trimming (trimming in different parts according to the desired material)

-

Bathing in drum (to remove the salt, dissolve the hair and rehydrate the skin)

-

Liming and fleshing (separating the hair from the hide and removing the natural fat)

-

Splitting (cutting of the hide to obtain different layers and thicknesses according to the desired material).

-

-

Tanning process (vegetable or chrome):

-

Descaling and pickling (certain components previously used are cleaned and the pH of the leather is adjusted for tanning): wet blue is obtained.

-

Pressing (excess water is removed)

-

-

Post-tannage process:

-

Trimming (the thickness of the leather is evened out)

-

v

-

Drying (the leather is left to dry in air-conditioned rooms)

-

Flattening/Fulling (the leather is stiffened and by a mechanical beating it is returned to its natural hand).

-

Finishing and refinishing (with another series of machinery the color, brightness, resistance and hand are given to the material).

-

-

Quality control process:

-

Selection (the leather is classified according to its quality)

-

Measuring (the leather is measured and stamped)

-

Packing (the leather is prepared for storage or shipment)

-

Knowing this now, do you think any leather item is expensive?

WHICH ARE THE GENERAL TYPES OF TANNING?

-

Vegetable: vegetable components such as nut shells and other components are used. They are more rigid and very natural finishes. They require great care

-

Chrome: they allow to give morbidity to the leather for different uses. Generally speaking, it does not require as much care as vegetable finishing.

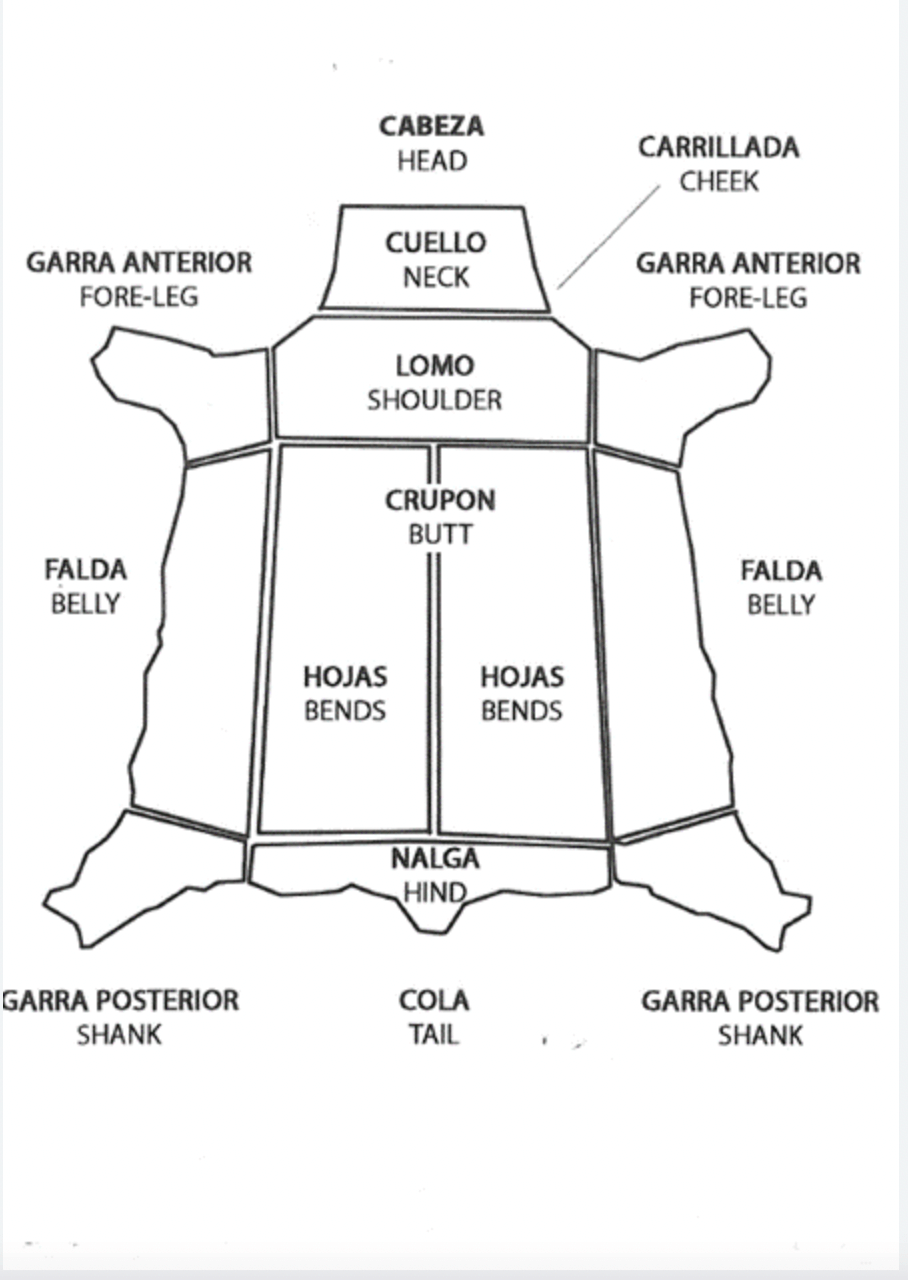

WHAT ARE THE PARTS OF THE LEATHER AND WHICH PART IS BETTER TO USE? FOCUSED ON COWHIDE

-

Whole skin: upholstery and large pieces that need very large patterns.

-

Neck: worked for vegetable items and belts.

-

Butt: perfect for belts since a certain length is needed.

-

Belly: also very worked for vegetable articles

WHAT IS LEATHER WORKING GROUP?

HISTORY

LWG was born in 2005 from a number of renowned agents in the sector to make a certificate recognized by all with the specifications and needs of the sector.WHO IS PART OF IT?

A multitude of actors from the entire value chain of the leather sector are part of the group.

From tanners to end brands.

WHO IS PART OF IT?

A multitude of actors from the entire value chain of the leather sector are part of the group.

From tanners to end brands.

WHAT ARE THE NEXT STEPS?

As indicated by the LWG itself https://www.leatherworkinggroup.com/fileadmin/uploads/lwg/Images/LWG_Traceability_Roadmap_.pdf

SUSTAINABILITY IN METAL ACCESSORIES

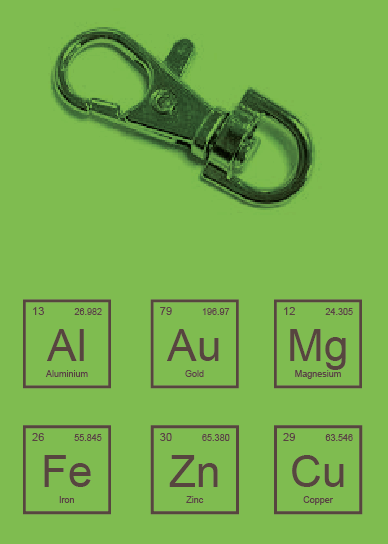

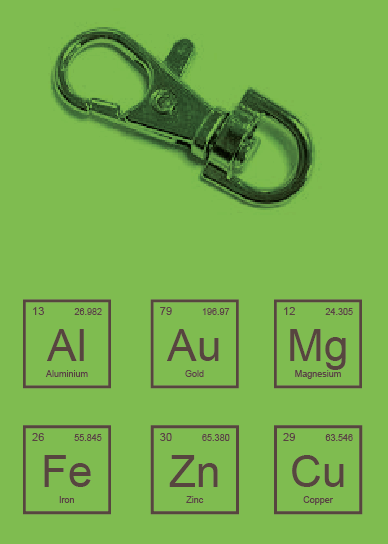

WHAT MATERIALS ARE NORMALLY USED AS A BASE?

-

Iron: more economical malleable metal. Needs a more specific polishing process as it is a porous material. Most commonly used in rivets, eyelets and chains. Designed for accessories that do not require a higher level of quality, usually used in advertising items.

Did you know that you can recognize iron thanks to a magnet? You will be attracted to it.

-

Aluminum: an aluminum alloy is mainly used to make chains. It is much lighter than iron and other metals. Very suitable for parts with large volume or needing to be light.

Did you know that it is the third most abundant element in nature? Only behind oxygen and silicon.

-

Zamac: alloy of Zinc, Aluminum, Magnesium and Copper. It is one of the most used metals in the leather goods and footwear accessory sector due to its balance between quality and price. The pieces are solid and resistant. Unlike iron and aluminum, they cannot be manipulated once finished.

-

Brass: this alloy is considered a high-end alloy for its quality and the excellent finish of the piece once done.

Did you know that it is a material used since prehistoric times?

What is galvanic?

It is the chemical process in which a thin layer of one metal is deposited on another. Once the piece is polished, the different thicknesses are deposited to achieve the required finish. As an example, for the gold finish, the set of layers are alkaline copper, acid copper, nickel and gold flash.

What are the most common finishes?

-

Gold

-

Light gold

-

Nickel

-

Black nickel

-

Antique brass

What does nickel free mean?

Nickel is considered to be a metal that can cause allergies when in contact with the skin. It is therefore replaced by other metals that are not harmful, such as white bronze, palladium...

|

|

Did you know that a gram of palladium is more expensive than a gram of gold? |

How can we talk about sustainability in forniture?

Avoiding heavy materials that are considered harmful to humans through contact, such as nickel, cadmium, lead and chromium.

The most important concept in sustainability in this market is the durability and quality of the piece.

Certificates

Depending on the accessory it is subjected to specific laboratory tests. For example:-

Salt spray corrosion test: the part is placed in an airtight chamber simulating altered salinity and pH conditions to check how they affect it and if any signs of corrosion appear.

-

Zipper fatigue test: the zipper is subjected to a continuous test of use cycles to check its durability and resistance to opening and closing.

-

Base metal composition analysis: a spectrometer/fisherscope is used to determine the thickness of each metal deposited on the part, indicating the quantity of microns.

Most common manufacturing processes

-

By stamping:

-

Raw material arrives in rolls

-

Stamping process in phases (the material is progressively beaten to give it the desired shape)

-

Oven (sometimes) : heat is applied to the piece to give it the desired strength.

-

Cleaning in the drum: after previous processes imperfections are removed with sand and other materials to avoid problems in the bath.

-

Galvanic bath: chemical process to deposit a thin layer of one metal over another.

-

Assembly: the different parts are assembled manually or automatically.

-

-

By foundry:

-

The raw material is melted

-

Injection: the molten material is injected into a mold and cold is applied to solidify it.

-

Polishing: specific manual or automatic machines are used to clean the imperfections of the part to avoid problems in the bath.

-

Galvanic bath: chemical process to deposit a thin layer of one metal on another.

-

Assembly: the different parts are assembled manually or automatically (depending on the final product, this can be done before the bath).

-

-

By numerical control:

-

This process is usually carried out with brass.

-

On the metal plate a casting is made to remove the excess metal and thus obtain the accessory. It is the opposite of 3D printing.

-

Polishing: After the casting, the imperfections and burrs of the part are rectified.

-

Galvanic bath: chemical process to deposit a thin layer of one metal on another.

-

Assembly: the different parts are assembled manually or automatically.

-

WHY LEATHER?

¿QUE ES LEATHER WORKING GROUP?

[accordions id='14992']